Flexible Rubber Magnets - Multi-Discipline Applications for the Future

10 Latest Application Scenarios:

As we all know from refrigerator stickers to car motors, billboards to medical devices. Gradually the field of application gradually become wide. As a ferrite, neodymium iron boron, samarium iron nitrogen magnetic powder in rubber combination of functional magnets, rubber magnets because of its own unique flexibility, processability, environmental protection, has become the industry in the consumer field of influence of the champion.

|

|

|

|

Ⅰ.Core Advantages of Rubber Magnetic: Why it can overturn the traditional magnetic material?

- Excellent physical properties

Flexible and moldable: it can be cut, punched and curled at will, and supports customized complex shapes (e.g. rolls, sheets, rings).

Strong environmental adaptability: working temperature ranges from -26℃ to 80℃, corrosion-resistant, aging-resistant, and the surface can be coated with PVC or double-sided tape to enhance functionality.

Safety and environmental protection: conforms to EN71, RoHS and other international standards, no toxic residue.

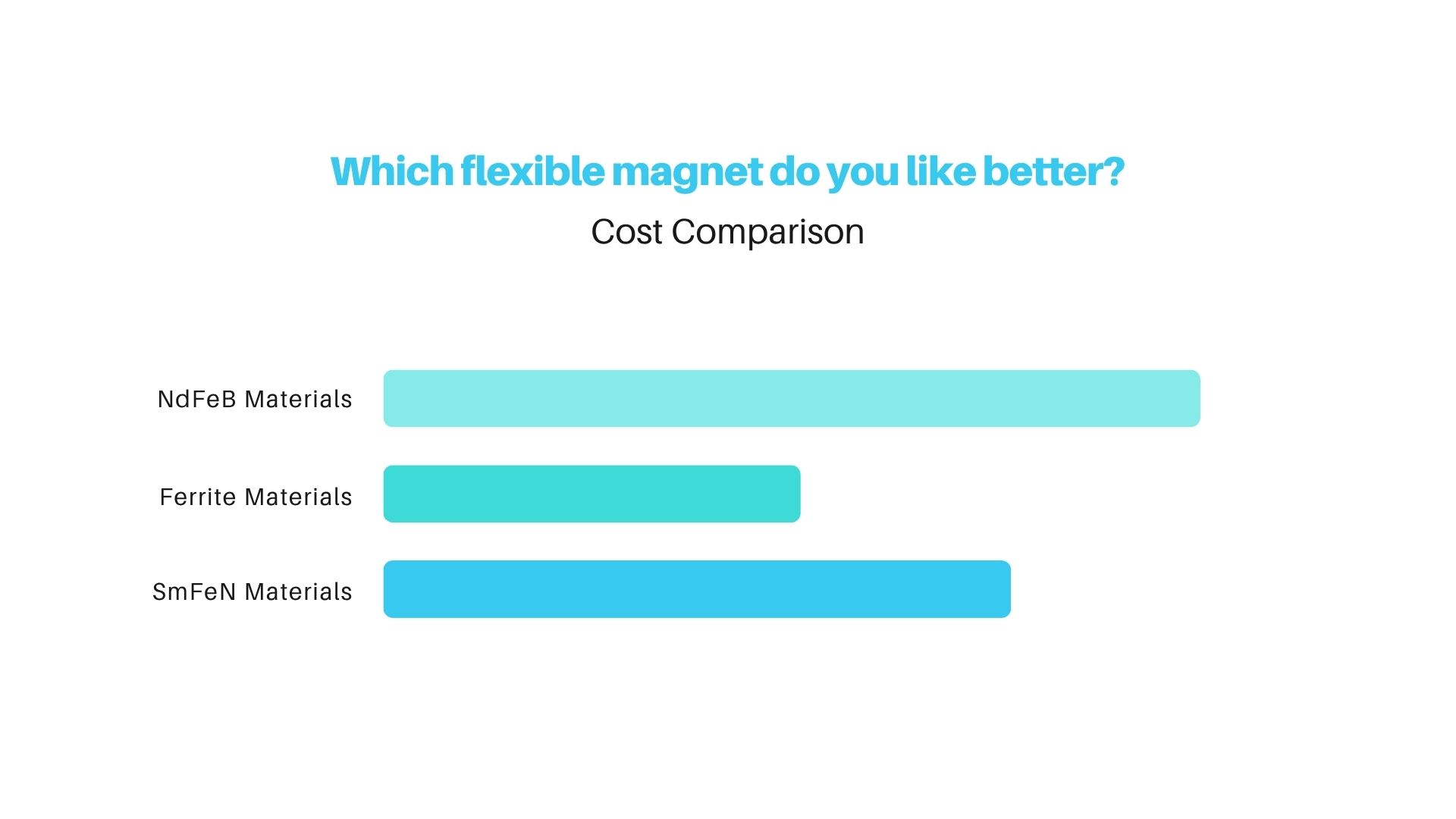

- Magnetic Property Grading Applications

| Type | Magnetic Strength | Application Scenarios |

| Isotropic rubber magnet | Weaker (100-300GS) | Refrigerator stickers, advertising signs, decorations |

| Anisotropic rubber magnet | Stronger (400-600GS) | Micro-motors, printer parts, high-precision toys |

- Low-cost and high-efficiency: Wide range of raw material sources, can be molded quickly by extrusion, calendering, and injection molding, reducing processing losses.

Ⅱ .Ten application areas: how to penetrate the rubber magnet into thousands of trades and industries?

1. Home and daily necessities

Decorative convenience: refrigerator stickers, magnetic photo frames, magnetic picture boards, both practical and interesting.

Functional upgrading: door and window sealing strip to improve the sound insulation and dustproof performance, magnetic mattress magnet for health care bedding.

2. Office and advertising

Flexible display: magnetic whiteboard labels, removable billboards, support repeated paste updates.

Creative design: 3M adhesive backing or color printing PVC, personalized logo (such as corporate logo, exhibition signage).

3. Automotive & Industrial

Lightweight fixing: car label sticking, lamp bracket, door lock spacer, replacing mechanical fasteners.

Intelligent warehousing: magnetic cargo labels, tool positioning boards, optimize workshop management efficiency.

4. Electrical & Electronic

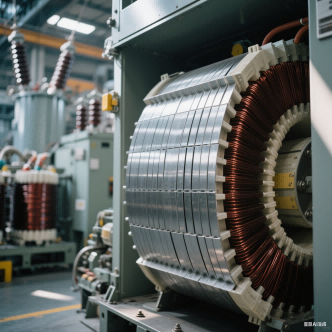

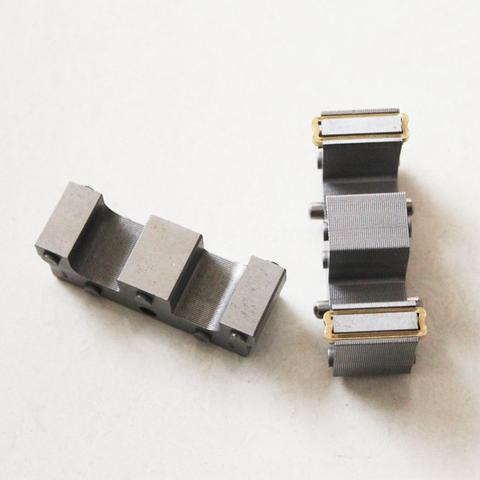

Precision components: computer cooling fans, air conditioner motors, printer drive components, relying on the high stability of anisotropic rubber magnets.

Electromagnetic protection: Shield electronic equipment interference, enhance product reliability.

5. Medical and Healthcare

Physical Therapy Devices: Magnetic therapy patches relieve pain and promote blood circulation.

Equipment fixation: Safe adsorption of medical instruments to avoid the risk of slipping off.

6. Educational toys

Enlightening tools: magnetic puzzles, letter modules, help children cognitive learning.

Safety design: no sharp edges, in line with toy safety standards.

Industry data insight: a family car needs to consume nearly 20kg of raw rubber production of rubber fittings15, while the rubber magnet penetration rate in microtome is over 60%11 - which confirms its irreplaceability in the industrial chain.

Ⅲ. Technological Evolution and Future Trends

- Material High Performance

New base materials such as fluoroelastomer and hydrogenated nitrile rubber enhance oil resistance and high temperature resistance (up to 176°F), and are adapted to new energy vehicle parts.

Thermoplastic elastomer (TPE) to replace traditional rubber, taking into account environmental protection and cost 15.

- Process Intelligence

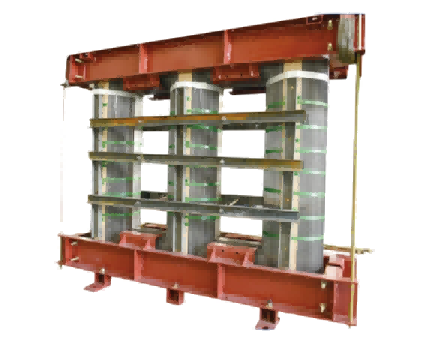

The integrated injection molding equipment achieves ±0.02mm precision (e.g., Daqo Robotics production line).

Magnetization process optimization: magnetization before vulcanization improves magnetic field stability, and magnetization after vulcanization simplifies the process.

- Application Innovation

Robot Collaboration: Explosion-proof rubber magnets are used in wheel coating robots, adapting to flexible production lines.

Medical exploration: Ultra-thin ECG patches with magnetized components to promote the upgrading of wearable devices.

- The era of “soft power” of rubber magnets

From household gadgets to industrial core components, rubber magnets crack rigid demands with flexibility and open up innovative scenarios with customizability. As the new quality productivity puts higher demands on materials, its evolution direction of “thin, light, strong magnetic and intelligent” will surely give rise to more cross-border applications.

In this era of pursuing flexibility and efficiency, the boundaries of rubber magnets only depend on our imagination.